Over 20 years, all the orders we strictly follow:

? Product Specifications: All customer specific units are produced by strictly following design and manufacture procedures based on customer samples and/or approved dimensional drawings.

? Raw material Specification: All materials, engineering processes and heat treatment levels are in accordance with your specifications.

We ensure the quality of our products in a variety of ways. Although the quality of our products has passed the international standard ISO9001: 2000 quality certification system, we require that all employees are involved in quality control process to achieve a truly high quality production environment, and create a multi-disciplinary approach to the quality of assurance system.

Our Quality Assurance personnel are well-trained professionals, using state-of-the-art equipment to verify that our products meet the specifications of the blueprint, to monitor the hardness, tensile strength, torque, tension, and resistance to corrosion and other factors are in line with your request. Furthermore, we are holding regular quality assurance meetings in order to maintain our focus on quality through integrating production workers, quality control personnel and senior management. Therefore, please rest assured that the quality of our product has passed and above the industry standards of Quality Assurance.

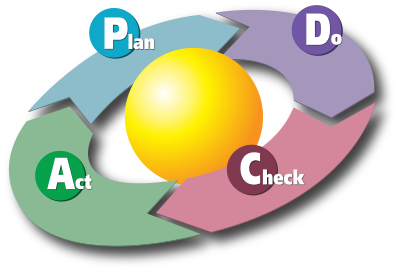

A basic operation can be described as:

Plan – Do – Check – Action management cycle, referred as PDCA cycle below

1.PLAN

Recognize an opportunity and plan a change. Establish the objectives and processes necessary to deliver results in accordance with the expected output. By making the expected output the focus, it differs from other techniques in that the completeness and accuracy of the specification is also part of the improvement.

2.DO

Test the change. Carry out a small-scale study. Implement the new processes, often on a small scale if possible.

3.CHECK

Measure the new processes and compare the results against the expected results to ascertain any differences. Study. Review the test, analyze the results and identify what you’ve learned.

4.ACT

Analyze the differences to determine their cause. Each will be part of either one or more of the P-D-C-A steps. Determine where to apply changes that will include improvement. When a pass through these four steps does not result in the need to improve, refine the scope to which PDCA is applied until there is a plan that involves improvement. Take action based on what you learned in the study step: If the change did not work, go through the cycle again with a different plan. If you were successful, incorporate what you learned from the test into wider changes. Use what you learned to plan new improvements, beginning the cycle again.